Showroom

Explore our range of Alloys engineered for reliability and performance. Crafted with precision, these alloyed elements offer durability and corrosion resistance, meeting stringent quality standards. Whether for automotive, aerospace, or other applications, the offered products deliver unmatched value and functionality.

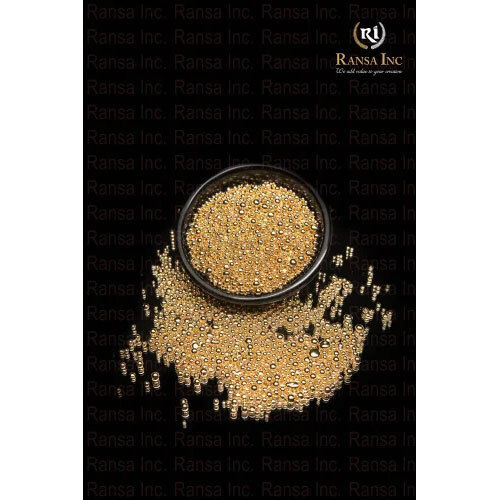

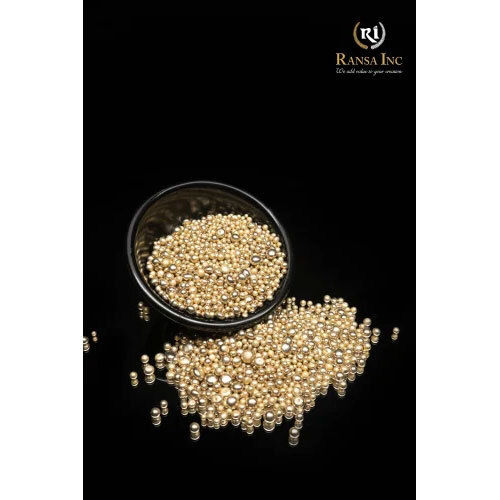

Master Alloys For Yellow Gold are specific kinds of metals, used for alloying with pure gold, in order to produce the required color, hardness, and other desirable characteristics in yellow gold jewelry. Yellow gold is widely used as a material in making high-end luxury watches. Its durability and aesthetics make it highly popular for use in watch cases and bands.

Universal Master Alloys For Yellow Gold Casting is a specific alloy that mixes with pure gold, which is 24K in the jewelry-making process, to produce yellow gold alloys for casting. The alloy can be used in any kind of yellow gold jewelry, including engagement rings, pendants, bracelets, and so much more. It can work on any karatage, with a consistency of color, durability, and workability.

Cadmium Free Solder Alloys are solders used in jewelry making and metalworking that do not contain cadmium, a toxic metal. They are designed to create reliable, long-lasting bonds that maintain the strength and integrity of the jewelry piece. This contributes to a cleaner, more sustainable jewelry-making process by reducing the amount of toxic materials that need to be managed and disposed of.

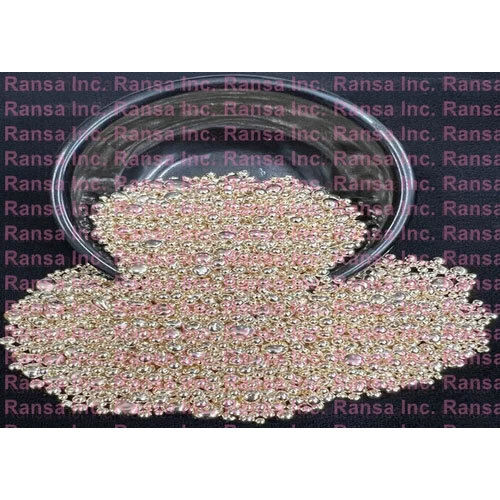

Master Alloys For Rose Gold are specifically formulated alloys used to mix with pure gold (24K) to create rose gold, a popular alloy known for its warm, pinkish-red hue. These alloys provide jewelers with the ability to control the alloy's color, strength, and workability, ensuring that each piece of rose gold jewelry meets the desired specifications.

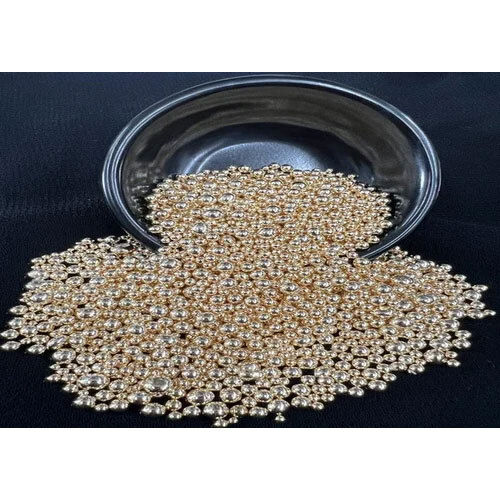

Brass Alloys are primarily copper and zinc, but often added by other elements, enhancing certain properties such as strength, corrosion resistance, or enhanced machinability. Brass is of course so easy to cast, machine, and from that mass production and even more one-of-a-kind pieces are possible. Brass alloys have a lovely golden color and are thus a popular choice in many decorative and jewelry applications.

Master Alloys For Fabrication refers to pre-formulated alloys made specifically to be added to base metals, such as gold, silver, or copper, during the fabrication process in metalworking and jewelry-making. These alloys can be used to make base metals easier to work with, improve casting, and produce a desired look and performance of the fabricated product.

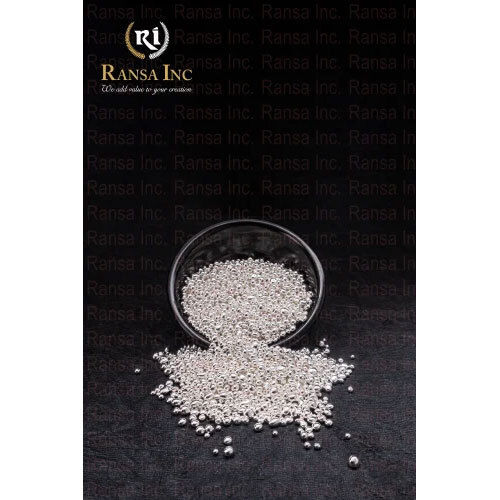

Silver Master Alloys are pre-alloyed silver materials that have been designed for use in creating various types of silver-based alloys, especially for jewelry, silverware, and industrial applications. This alloy carefully produces specific characteristics such as strength, color, malleability, and durability to meet the desired standards of quality and performance.

Master Alloys With Nickel Silver Based White Gold refers to specialty alloys manufactured through the amalgamation of nickel, silver, and other elements for the specific production of white gold alloy appropriate for jewelry usage. These have the advantage of being affordable and having a longer shelf life in addition to that silvery colouring that can be used on top-of-range jewelry.

The term Brass Casting pertains to a technique where molten brass is formed into the required shape or product by pouring into a mold. This casting procedure allows the mass production of intricately detailed brass pieces used in several applications, ranging from jewelry to art pieces to industrial machinery and plumbing. More often than other manufacturing methods like machining or forging, it's cheaper for the more complex shapes.

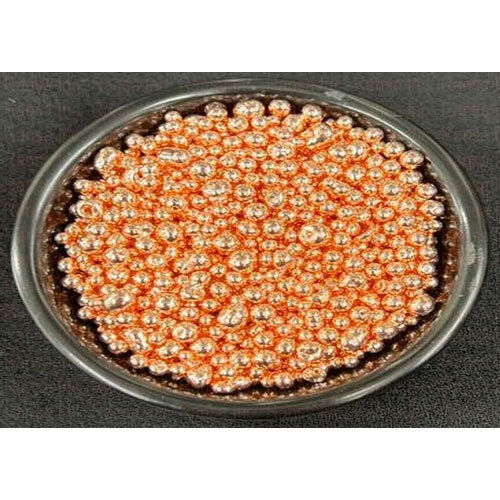

Copper Alloys are alloys of copper combined with other metals or elements to enhance its properties, such as strength, corrosion resistance, electrical conductivity, and heat resistance. The alloys retain high electrical conductivity, making them suitable for electrical wiring, connectors, and electrical components. The combination of copper with other metals gives the alloy unique characteristics that make it suitable for specific uses.

Ready Silver Solder is a pre-manufactured alloy used for jewelry making, metalworking, and other precision applications to join silver and other metals. It is an easy, reliable method for joining metal components and comes in different grades depending on the specific application and requirements of the project. The alloy composition and melting point are already determined by ready silver solder to ensure performance and results.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free